You must tape your drywall seams to maintain structural integrity and prevent serious wall issues. Taping reinforces joints against movement, stops moisture infiltration, and prevents cracking that can occur when using compound alone. Without proper taping, your walls become vulnerable to damage, mold growth, and costly repairs. Professional contractors emphasize that skipping this critical step leads to premature wall failure. Understanding proper taping techniques will help you achieve professional-grade results that last.

Key Takeaways

- Drywall tape acts as crucial reinforcement to prevent seams from cracking and separating due to structural movement and settling.

- Without tape, drywall compound alone will shrink and crack over time, leading to visible wall damage and costly repairs.

- Taping creates a moisture barrier at seams, protecting against water infiltration and potential mold growth in the walls.

- Proper taping significantly increases wall durability and impact resistance, especially in high-traffic or movement-prone areas.

- Taped seams provide the necessary foundation for achieving a smooth, professional finish that lasts for years without visible joints.

The Structural Role of Drywall Tape

Although drywall installation may seem straightforward, the tape used to join seams plays a crucial structural role that goes beyond mere aesthetics. When you’re joining drywall sheets, you’re creating points where structural movement can cause cracking and separation. That’s where tape becomes your indispensable reinforcement system. Professional contractors like Calgary Drywall Doctors understand that proper taping prevents moisture issues and mold growth in basement installations.

Common Types of Drywall Tape and Their Benefits

Selecting the right drywall tape can greatly impact your project’s durability and finish quality. You’ll find paper tape offers superior strength for flat seams, requiring drywall joint compound for proper adhesion. When you’re working in areas prone to movement or need repairs, fiberglass mesh tape‘s self-adhesive quality and mold resistance make it your ideal choice.

For specialized applications, you’ve got options that meet specific needs. Vinyl tape excels on curved surfaces, while metal tape provides exceptional strength for high-stress areas. When you’re finishing outside corners, preformed tape guarantees both structural integrity and professional results. Remember, each type serves a distinct purpose in your drywall project, and choosing the appropriate tape will assist you in achieving those clean, strong joints that every professional installation demands. Our skilled technicians ensure proper tape selection and application for both residential and commercial projects to maintain the highest quality standards.

Risks of Skipping the Taping Process

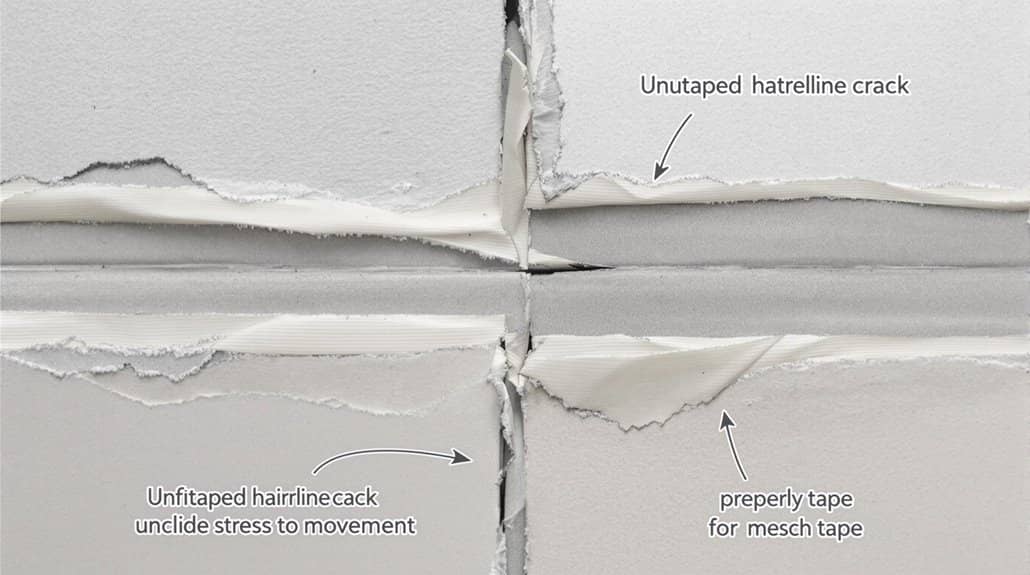

When you’re tempted to skip the taping process during drywall installation, you’re risking serious structural and aesthetic problems that can plague your project for years. Without proper taping and mudding, your drywall compound won’t provide the necessary reinforcement to prevent seams from cracking and separating during normal building movement.

You’ll face increased vulnerability to moisture infiltration, which can lead to mold growth and compromise your walls’ integrity. The drywall compound alone won’t maintain a smooth surface over time, as it’s likely to shrink and crack without tape reinforcement. Your walls will also be more susceptible to impact damage and everyday wear. By skipping this vital step, you’re setting yourself up for costly repairs and supplementary work that could have been avoided with proper taping techniques. For best results, consider working with professional drywall services that offer satisfaction guarantees to ensure your project is completed correctly the first time.

Professional Taping Techniques and Best Practices

Mastering professional drywall taping techniques starts with proper tape embedding. To create a strong bond, you’ll need to press the tape into a thick layer of compound while maintaining a consistent 60-degree angle with your taping knife. This technique creates an even distribution and eliminates troublesome air bubbles.

When finishing drywall, your choice of tape matters. While mesh tape offers self-adhesive convenience for DIYers, paper tape requires more skill but delivers superior results. You’ll want to keep the compound layer no thicker than 1/16 inch to prevent dimpling. Equip yourself with crucial tools like a mud pan, hawk, and different taping knives for peak control. Remember to regularly check your work – proper adhesion is critical. A well-embedded tape creates a seamless finish that prevents future cracking and guarantees professional-quality results. For optimal sound control and insulation, professional contractors utilize modern installation methods paired with top-quality materials.

Essential Tools and Materials for Proper Taping

Three core tools form the foundation of professional drywall taping: a quality mud pan, properly sized taping knives, and a reliable hawk for compound management. You’ll need these fundamentals, along with proper safety gear, to achieve professional results when applying joint compound and tape.

| Tool | Purpose |

|---|---|

| 5-6″ Taping Knife | Primary coat application |

| Mud Pan | Controlled compound handling |

| Hawk | Efficient mud distribution |

| Damp Sponge | Surface smoothing |

| Safety Mask | Dust protection |

Before you begin taping, verify you’ve gathered all your materials and donned appropriate safety gear. Your mud pan will help control drywall mud application, while properly sized knives enable smooth, even coverage. Don’t forget to keep a damp sponge handy for surface refinement before the compound dries. Having these tools ready streamlines your workflow and helps you achieve professional-grade results.

Joint Compound Selection and Application Methods

Choosing the right joint compound stands as the foundation of successful drywall taping. You’ll want to select a heavyweight all-purpose compound for embedding tape, as it provides superior strength compared to lightweight alternatives. When making your joint compound selection, consider whether you need a drying-type joint compound or a setting-type variety based on your project’s timeline.

Before application, mix your compound thoroughly to achieve a consistent texture that’ll spread smoothly. Using your taping knife (5- or 6-inch recommended), apply thin layers no thicker than 1/8 inch over the seams. This technique helps prevent shrinkage issues and guarantees better adhesion. Remember, multiple thin coats will give you better results than one thick application. By following these methods, you’ll create stronger joints and achieve that professional-quality finish you’re aiming for.

Time-Tested Tips for Long-Lasting Drywall Seams

Now that you’ve got your joint compound ready, let’s focus on proven techniques that guarantee your drywall seams stand the test of time. When you’re applying tape and mud, position your drywall tape at a 60-degree angle for ideal embedding. You’ll want to use heavyweight joint compound for superior adhesion and crack resistance.

Remember to work in thin layers, removing excess compound as you go. This approach prevents shrinkage issues and minimizes your sanding workload later. As a professional best practice, always allow each coat to dry completely before adding the next layer. You’ll need to inspect your work regularly, ensuring the tape adheres properly to the drywall surface. By following these time-tested methods, you’re joining the ranks of skilled installers who create seamless, durable walls that last for years. Professional drywall services can help you avoid costly mistakes and ensure long-lasting results.

Frequently Asked Questions

What Happens if I Don’t Tape Drywall Seams?

You’ll compromise your drywall integrity with basic installation errors. Without proper finishing techniques like taping, your walls will develop cracks, moisture problems, and unsightly gaps that’ll require expensive repairs down the road.

Do You Always Need to Tape a Drywall Patch?

Yes, you’ll need to tape your drywall patches for proper structural integrity. Whether using mesh or paper tape types, all professional patching techniques and repair methods require taping to prevent future cracking and guarantee lasting results.

What Is Drywall Seam Tape For?

You’ll use drywall seam tape to reinforce joints between panels, preventing cracks and ensuring structural stability. Whether you choose paper or mesh tape, it’s crucial for creating smooth, professional-looking walls that’ll last longer.

How Does Drywall Tape Prevent Cracks?

Your drywall tape’s adhesive properties create a strong barrier that prevents cracks by distributing wall stress. It also improves moisture resistance and reinforces joints, ensuring you’ll have stable, crack-free seams for years to come.

Conclusion

Properly taping your drywall seams isn’t optional – it’s crucial for structural integrity and code compliance. You’ll need to select appropriate tape and joint compound, follow professional application techniques, and maintain proper drying times between coats. Don’t rush this critical process, as mistakes can lead to costly repairs. When you invest the time in proper taping methods, you’ll achieve durable, crack-resistant walls that will last for decades.