Your drywall installation costs depend on several key variables. Project size and complexity directly impact material quantities and labor hours, while your choice of specialized materials like moisture-resistant or fire-rated panels can increase expenses by 20-25%. Labor rates vary by region ($40-80/hour for experienced contractors), and market conditions affect material availability and pricing. Room accessibility and custom features like rounded corners require extra expertise. Understanding these interconnected factors will help you navigate your project’s budget more effectively.

Key Takeaways

- Project size directly impacts material quantity and labor hours, with larger spaces requiring more resources and time to complete.

- Material quality choices affect costs significantly, with specialized options like moisture-resistant panels adding up to 25% to expenses.

- Labor rates vary by region and expertise level, ranging from $30-$80 per hour depending on contractor experience.

- Additional features like soundproofing, moisture resistance, or custom corners increase both material costs and required labor expertise.

- Market conditions and seasonal demand influence pricing, with off-peak installation potentially offering cost savings.

Project Size and Complexity Considerations

Two key factors drive drywall installation costs: project size and design complexity. You’ll find that larger spaces require more drywall sheets and extended labor hours, directly impacting your material and labor costs. For instance, a 12′ x 20′ primary bedroom typically ranges from $750 to $2,600, depending on these variables.

When planning your drywall installation, consider how the intricacy of the project affects your cost estimate. Intricate designs, such as rounded corners or complex layouts, demand specialized skills and increase labor costs compared to standard installations. The installation area’s accessibility also plays an essential role – hard-to-reach spaces require extra time and effort. You’ll save money with smaller, simpler rooms due to reduced material needs and straightforward installation processes. Professional contractors charge labor costs between $30 to $70 per hour for skilled installation and finishing work.

Material Quality and Selection Impact

Material selection stands as a critical cost determinant in your drywall installation project. When you’re planning your investment, understand that specialized materials like fire-resistant and soundproof drywall will increase your installation costs considerably. Moisture-resistant options for bathrooms and kitchens typically add 25% to your project expenses, while thicker sheets cost up to 20% more than standard panels. Purple drywall options provide superior moisture and mold protection for basement installations, making them a worthwhile investment despite higher initial costs.

Consider these key factors that impact your cost of drywall installation:

- Specialized materials require skilled labor, increasing hourly rates by 10-30%

- High-quality materials reduce long-term expenses by 10-15% through decreased maintenance needs

- Moisture-resistant and fire-resistant options provide targeted solutions for specific rooms

Labor Expertise and Regional Rates

While drywall installation appears straightforward, labor expertise greatly influences your project’s final cost and quality. You’ll find that average labor costs range from $1.30 to $1.60 per square foot, with experienced contractors commanding $40 to $80 hourly rates compared to less seasoned workers at $30 to $50. Regional rates notably impact your drywall installation costs, as market demand and local pricing structures vary by location. When planning your project, consider that complexity plays a vital role – intricate designs require higher expertise and may extend completion timelines. To guarantee you’re getting competitive pricing, it’s important to gather multiple contractor quotes. This approach helps you understand local market rates while identifying professionals whose expertise aligns with your project’s specific requirements and regional cost expectations. Planning your installation during the off-season months can result in better rates and more personalized attention from contractors.

Additional Features and Specialty Requirements

Beyond standard installation considerations, specialty features greatly influence your total drywall project costs. When you’re planning your installation, you’ll need to account for supplementary features that serve specific purposes in different areas of your space.

Consider these key specialty requirements that impact your project expenses:

- Soundproofing solutions using dense, specialized drywall for noise reduction

- Moisture-resistant drywall for bathrooms and kitchens, featuring premium material designed for high-humidity environments

- Fire-resistant options with fiberglass reinforcement for improved safety in critical areas

Custom features like rounded corners require extra skill and labor, while incorporating insulation demands extra materials and expertise. These specialty requirements affect your installation costs but provide crucial functionality for your specific needs. Understanding these elements helps you budget effectively for your drywall project. Experienced contractors typically charge higher rates for specialty installations, reflecting their advanced expertise with complex requirements.

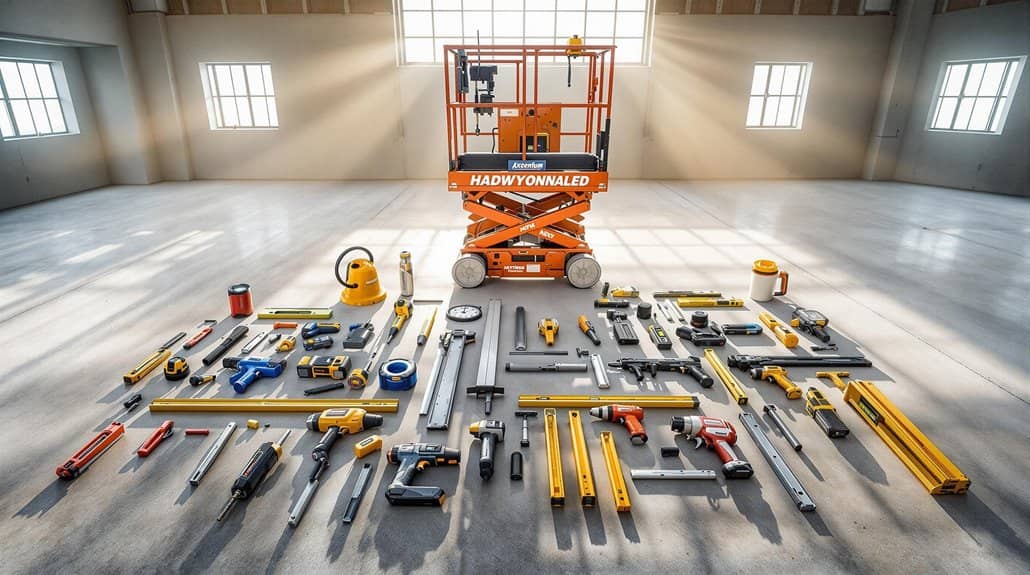

Equipment and Tool Considerations

Professional drywall installation requires three vital categories of equipment: standard hand tools, specialized installation aids, and safety equipment. You’ll find that investing in quality tools, like power screwdrivers and automatic tapers, greatly improves installation efficiency while reducing labor costs. For handling heavy drywall sheets safely, specialized aids such as drywall lifts are important, especially in complex installations.

Your cutting tools, including utility knives and drywall saws, must be of high quality to guarantee precise cuts and professional results. While equipment rental for larger items like scaffolding will impact your entire budget, it’s often necessary for challenging projects. Keep in mind that proper tool maintenance improves productivity and keeps your project timeline on track. Well-maintained equipment prevents unexpected delays and helps maintain consistent quality throughout the installation process. Our highly trained team ensures all equipment is properly maintained and utilized for maximum efficiency and superior results.

Timeline and Scheduling Factors

Since drywall installation follows a predictable sequence, you’ll need to plan for a typical three-day timeline with 6-7 hour workdays. Your project timeline can fluctuate based on several key factors that impact scheduling and potentially lead to unexpected costs.

Consider these critical scheduling elements for your installation:

- Weather conditions can affect material integrity, requiring delays until conditions improve

- Contractor availability varies by season, so book early to secure skilled labor

- Project size and accessibility of work areas determine actual completion time

When planning your timeline, factor in potential material shortages and building complications that might extend the schedule. Your contractor should assess the workspace accessibility and provide a detailed project timeline that accounts for these variables, helping you avoid costly delays and ensuring a smooth installation process. Working with experienced technicians ensures precise execution and minimizes the risk of timeline disruptions.

Market Conditions and Supply Chain Effects

Market conditions and supply chain dynamics play a pivotal role in determining your drywall installation costs. When you’re planning your construction project, you’ll need to evaluate how material availability and transportation costs directly impact your bottom line. Supply chain disruptions can affect gypsum procurement and delivery timelines, while seasonal variations in contractor demand may influence your project’s pricing. Commercial drywall services are particularly susceptible to these market fluctuations due to larger project scopes.

| Market Factor | Impact on Costs |

|---|---|

| High Demand | Increased drywall prices |

| Supply Disruptions | Extended lead times |

| Transportation Issues | Higher delivery costs |

| Seasonal Peak | Premium contractor rates |

To optimize your project’s budget, monitor market conditions closely and assess scheduling your drywall installation during off-peak seasons. Working with contractors who maintain strong supplier relationships can help mitigate the effects of supply chain challenges and secure more favorable pricing for your installation.

Frequently Asked Questions

How Do You Calculate Labor Cost for Drywall?

You’ll need to multiply labor rates by total square footage, factoring in geographic location, project complexity, crew size, and job duration. Don’t forget to contemplate experience level and seasonal demand for accurate cost calculations.

What Is the Rule of Thumb for Drywall Estimating?

You’ll need one 4×8 drywall sheet per 32-48 square feet of wall area, plus 10% for waste. Consider material quality and finishing options when calculating your project’s scope and tool requirements.

How Much Does It Cost per Square Foot to Install Drywall in Canada?

You’ll typically spend between CAD $1.50 to $3.00 per square foot for drywall installation in Canada, with variations based on your project size, material selection, contractor rates, and regional pricing differences.

How to Budget for Drywall?

Calculate your total square footage, multiply by $2/sq.ft for basic costs, add 10-20% contingency, and factor in material choices and labor rates. Compare contractor quotes and consider DIY vs. professional installation for budget optimization.

Conclusion

Multiple cost determinants shape your drywall installation budget. You’ll need to factor in project scale, material specifications, labor rates, and specialty requirements while accounting for equipment needs and timeline constraints. Your project’s success depends on balancing these variables against current market conditions and supply chain dynamics. Optimize costs by carefully evaluating each factor and adjusting your specifications to meet both quality standards and budgetary requirements.